What Is a Service Entrance Cable?

Service entrance cables are electrical cables that connect and carry electrical currents from electrical companies to commercial buildings. They come in different types that serve various functions. Read on to learn what service entrance cables are and their primary characteristics.

Service Entrance Cables

There are two main types of service entrance cables: SER and SEU. SER cables are with a Style R reinforcement tape, and they typically deliver power from the service drop-down to the meter base to the distribution panel. SEU cables are most frequently used as panel feeders in branch circuit applications.

According to the National Electric Code (NEC), service entrance cables are designed to be used for services. All service entrance cables are produced, tested, and marked according to UL 854 standards. Service entrance cables for underground use are UL Type USE or USE-2, and service entrance cables for aboveground use are UL Type SE, Style R or U. Contact us today to see which cable type best suits your needs!

Service Entrance Cable Characteristics

Aboveground service entrance cables are either SER or SEU. They have a moisture-resistant and flame retardant covering that enables them to easily pull through framing members and wooden joists in commercial buildings. Installation and application of all service entrance cables are specified by NEC Article 338.

Conductor Materials

SEU and SER cables are manufactured with an AA-8000 series (ACM) electrical-conductor-grade aluminum alloy. Manufacturing underground UL Type USE and USE-2 cables that are not marked with any other type—such as RHH, RHW, or RHW-2—is done with an AA-8000 series (ACM) electrical-conductor-grade aluminum alloy or an EC-1350 grade aluminum alloy.

SER and SEU cables have different anatomies that make them suitable for various parts of a project. For example, an SEU cable has a neutral conductor but lacks a ground conductor. Because ground conductors and neutral conductors are only joined at the point of service disconnect, SEU cables are only safe to use at the point of disconnect. On the other hand, SER cables have both neutral and ground conductors, which makes them safe to use after the service disconnect.

Another difference between SER and SEU cables is their construction. SER cables are copper or aluminum wires reinforced with special Style R tape. SEU cables are Style U, which means they are unarmored and often used as panel feeders. Regardless of type, the installation of service entrance cables should always be done by a professional for safety reasons.

Service Entrance Cables From Classic Wire and Cable

Now that you have a good understanding of SER and SEU cables, the next step is to select a cable that fits your particular electrical project. With more than 200 years of combined cable and wire experience, Classic Wire and Cable’s experts specialize in serving electrical distributors. With warehouses in California and Pennsylvania and regional distribution centers throughout the U.S., we are always fully stocked with high-quality goods at competitive prices. Reach out for a quote on any of our products!

Ratings and Markings

See this table to learn more about our service entrance cable specifications.

| Cable | SE Style R | SE Style U | USE–2 | Mobile Home

Feeder |

| Number of

Conductors |

2c + Bare Cabled 3c + Bare Cabled 4c + Bare Cabled | 2c + Bare Concentric | 1c | 3c + Insulated Ground |

| Aluminum

Conductor Size |

8 AWG to

300 kcmil |

8 AWG to

4/0 AWG |

8 AWG to

1000 kcmil |

2 AWG to

4/0 AWG |

| Conductor

Insulation |

Thermoplastic (UL 83)

Thermoset (UL 44) |

Thermoset (UL 44) | ||

| Conductor Types | UL 83: THHN / THWN-2

UL 44: XHHW |

RHH / RHW-2 / USE-2 | ||

| Covering | Overall Tape-and-Finish | N/A | N/A | |

| Covering Material | 75 deg C PVC | N/A | N/A | |

| Covering

Thickness |

Minimum Average: 30 mil

Minimum Point: 25 mil |

N/A | N/A | |

| Sunlight Resistant | YES | YES | YES | YES |

| Impact and

Crush Tested |

NO | NO | YES | YES |

| Direct Burial | NO | NO | YES | YES |

| Joist Pull Tested | YES | YES | NO | NO |

| Overload Test | YES | YES | ||

Selecting the right service entrance cable depends on the priorities of your electrical project. At Classic Wire and Cable, we offer a range of value-added services and use all available resources to make our customers’ projects a success. Contact us today for more information about our products and services.

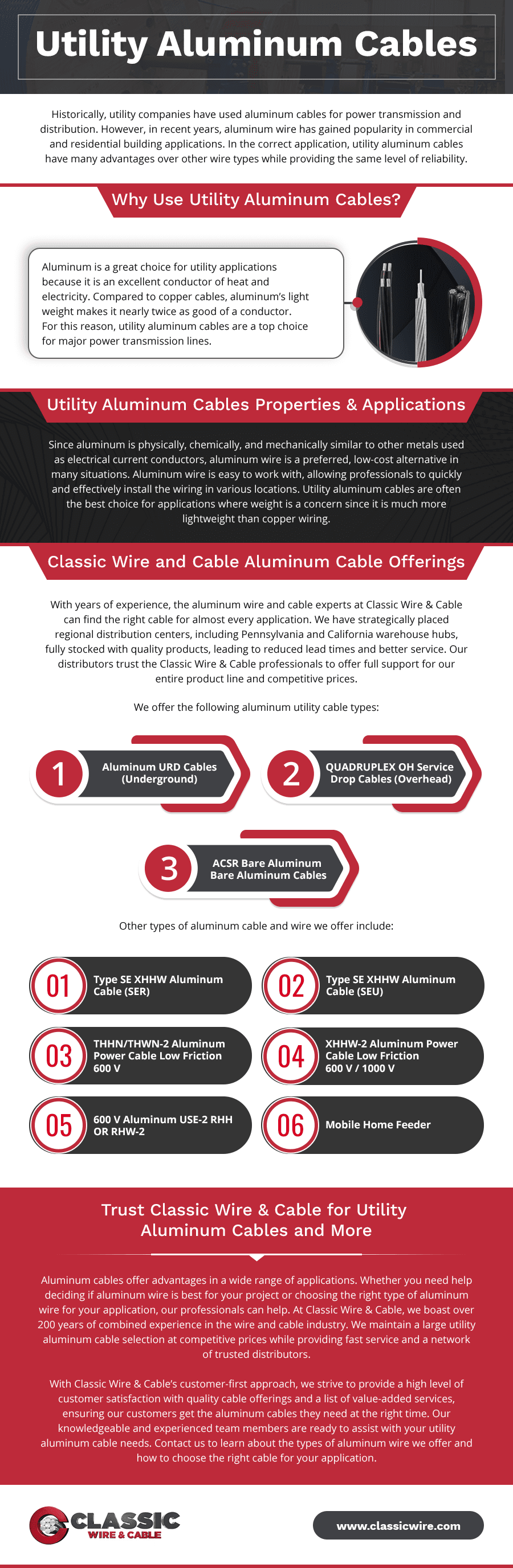

Utility Aluminum Cables & Wires

Historically, utility companies have used aluminum cables for power transmission and distribution. However, in recent years, aluminum wire has gained popularity in commercial and residential building applications. In the correct application, utility aluminum cables have many advantages over other wire types while providing the same level of reliability.

At Classic Wire & Cable, our collective experience in the cable and wire industry exceeds 200 years, enabling us to exclusively provide electrical distributors with high-performance aluminum cables.

Why Use Utility Aluminum Cables?

Aluminum is a great choice for utility applications because it is an excellent conductor of heat and electricity. Compared to copper cables, aluminum’s light weight makes it nearly twice as good of a conductor. For this reason, utility aluminum cables are a top choice for major power transmission lines.

Utility Aluminum Cables Properties & Applications

Since aluminum is physically, chemically, and mechanically similar to other metals used as electrical current conductors, aluminum wire is a preferred, low-cost alternative in many situations. Aluminum wire is easy to work with, allowing professionals to quickly and effectively install the wiring in various locations. Utility aluminum cables are often the best choice for applications where weight is a concern since it is much more lightweight than copper wiring.

The construction industry uses aluminum wire because of its cost savings and better conductivity to weight than other wiring types, such as copper. Contractors install aluminum wire in multiple areas, such as service entrance conductors, large conductors, and power distribution conductors. Commercial facilities widely use utility aluminum cable, including high-rise buildings, shopping malls, stadiums, wastewater treatment plants, and manufacturing facilities.

Check Out Our Utility Aluminum Cables!

Classic Wire and Cable Aluminum Cable Offerings

With years of experience, the aluminum wire and cable experts at Classic Wire & Cable can find the right cable for almost every application. We have strategically placed regional distribution centers, including Pennsylvania and California warehouse hubs, fully stocked with quality products, leading to reduced lead times and better service. Our distributors trust the Classic Wire & Cable professionals to offer full support for our entire product line and competitive prices.

We offer the following aluminum utility cable types:

- Aluminum URD Cables (Underground)

- QUADRUPLEX OH Service Drop Cables (Overhead)

- ACSR Bare Aluminum Bare Aluminum Cables

Other types of wire and cable we offer include:

- Type SE XHHW Aluminum Cable (SER)

- Type SE XHHW Aluminum Cable (SEU)

- THHN/THWN-2 Aluminum Power Cable Low Friction 600 V

- XHHW-2 Aluminum Power Cable Low Friction 600 V / 1000 V

- 600 V Aluminum USE-2 RHH OR RHW-2

- Mobile Home Feeder

See All Our Wires and Cables Here!

Trust Classic Wire & Cable for Utility Aluminum Cables and More

Aluminum cables offer advantages in a wide range of applications. Whether you need help deciding if aluminum wire is best for your project or choosing the right type of aluminum wire for your application, our professionals can help. At Classic Wire & Cable, we boast over 200 years of combined experience in the wire and cable industry. We maintain a large utility aluminum cable selection at competitive prices while providing fast service and a network of trusted distributors.

With Classic Wire & Cable’s customer-first approach, we strive to provide a high level of customer satisfaction with quality cable offerings and a list of value-added services, ensuring our customers get the aluminum cables they need at the right time. Our knowledgeable and experienced team members are ready to assist with your utility aluminum cable needs. Contact us to learn about the types of aluminum wire we offer and how to choose the right cable for your application.

Industrial Wire & Cable Types

Wires and cables are integral components for a wide range of commercial and industrial applications. At Classic Wire and Cable, we offer a full product line of industrial wire and cables, competitively priced to meet the demands of our customers. Each product has a particular use and provides various benefits.

Industrial Wire Types

- Wiring power grids

- Overhead power transmission lines

- Local power distribution lines

- Power wiring of airplanes

From the late 1800s to the early 1900s, utility companies used aluminum wire in power grids for electrical transmission. The cost and weight advantages of the lightweight metal outweighed that of copper wiring.

Today, aluminum wire is still the preferred material in power transmission and distribution applications. Since copper is a better conductor than aluminum, most home wiring projects and small applications use copper wires. However, in the 1960s, when the price of copper skyrocketed, aluminum wiring became the preferred choice for home wiring.

Industrial Cable Types

There are several industrial cable types to choose from, each having its own unique uses and advantages:

Type MC Armored Cables

Metal-clad (MC) armored cable constructions offer a cost-efficient alternative to traditional wire and pipe. This industrial cable type eliminates the need for an electrical conduit, thereby reducing the labor costs typically involved with installation.

Contractors that use MC armored cable require:

- Limited pulling equipment

- Fewer reels

- Less time setting up pulls

- No specialty bending or cutting tools

Key advantages of armored cable include:

- Protection and durability. These cables provide the necessary protection and durability without needing an electrical conduit, costly offsets, elbows, and conduit couplings.

- Corrosion resistance. Armored cable resists corrosion, making them suitable for locations exposed to excessive moisture.

- Flexibility. The interlocked armor material is flexible, unlike continuously welded armor or other conduits, offering protection to the inner conductors. MC armored cable is also easy to install in complex, close-spaced bends.

- No specialty tools. Installation does not require specialty cutting or bending tools.

A variety of industries utilize aluminum cables due to their many benefits. Even though aluminum is much lighter than copper, it maintains the same conductivity properties, giving it a distinct advantage compared to other metals. When weight is a primary concern, as in load-bearing jobs, aluminum cables are preferred because of their lightweight yet durable design.

When comparing copper cables to aluminum cables on a loading basis, aluminum offers several different advantages, including:

- More cost-effective

- Lighter in weight

- Has the same conductivity

SO Portable Cord Cables (Copper)

SO Portable Cord Cables (Copper)

It is common practice to identify the properties of industrial wire and cable with a letter. With SO portable cord cables, the “S” stands for “Extra Hard Service,” and the “O” stands for “Oil Resistant.” This means that this type of industrial cable is ideal for applications requiring 600 volts or less, and its outer jacket is resistant to oil.

Experienced Wire and Cable Manufacturers

Many industries, such as construction, rely on industrial electric wire and cable components for various projects. Classic Wire and Cable has exclusively provided quality products to electrical distributors since 2016. We have two fully stocked warehouse hubs in California and Pennsylvania, with several strategically located regional distribution centers.

Our knowledgeable sales team and local NEMRA-affiliated representatives offer invaluable resources in selecting the proper industrial cable types to help our clients succeed. As a preferred supplier, Classic Wire and Cable offers Value Added Services and a wide variety of quality industrial wire and cable products, including those listed above.

If you can’t find the product you are looking for, contact us today, and one of our sales representatives can assist you. We’d be happy to provide you with more information about our catalog of products.

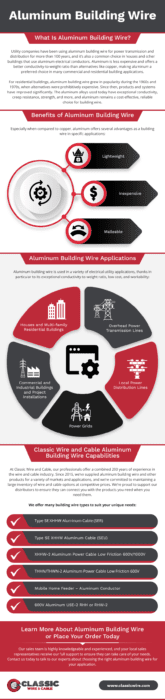

Aluminum Building Wire & Cable

Classic Wire & Cable offers high-quality aluminum building wire for your residential, commercial, and industrial electrical projects.

We prioritize safety, ensuring all our aluminum building wire and cable meets industry standards like UL and RoHS compliance. Our vast distributor network makes it easy to find the right wire for your needs.

What Is Aluminum Building Wire?

For over 100 years, utility end users have relied on aluminum building wire for efficient power transmission and distribution. The reasons are clear: aluminum is cost-effective and boasts a superior conductivity-to-weight ratio compared to alternatives like copper.

Modern aluminum alloys used in building wire offer exceptional conductivity, improved creep resistance, and increased strength, solidifying aluminum’s position as a reliable and cost-effective choice for electrical wiring.

What Are the Benefits of Aluminum Building Cable and Wire?

Compared to copper, aluminum building wire offers distinct advantages in several applications:

- Lightweight Champion: During construction, every pound counts. While slightly larger than copper wire of similar conductivity, aluminum building cable weighs about half as much. This translates to significant weight reduction on large projects without compromising performance.

- Cost-Effective Choice: Aluminum is often half the price of copper. While it may have slightly lower corrosion resistance, the substantial cost savings often outweigh this factor. For applications with minimal exposure to corrosion, aluminum cable becomes even more affordable, especially for large-scale projects requiring significant wire lengths.

- Easy to Maneuver: Aluminum’s flexibility makes it easier to work with than copper, particularly for long runs and confined spaces.

Choosing the Right Wire

Remember, project specifics matter. Consider the pros and cons of various building wire types to ensure they meet your needs. In many cases, aluminum will be your project’s most practical, cost-effective, and durable choice. We’re happy to help you select the best option for your specific application.

What Are Some Common Aluminum Wire Building Applications?

Aluminum building wire is often used in electrical utility applications due to its exceptional conductivity-to-weight ratio, low cost, and workability:

- Overhead power transmission lines

- Local power distribution lines

- Power grids

- Commercial and industrial buildings and project installations

- Houses and multi-family developments

With its lightweight durability, aluminum cabling has a place in the aerospace, automotive, construction, and transportation industries.

How Does Classic Wire & Cable Help?

Classic Wire & Cable offers a comprehensive selection of aluminum building wire to meet your electrical application needs. Our Team, with over 200 years combined experience, we are committed to providing high-quality products, competitive prices, and exceptional customer service. Our aluminum product line includes the following:

- Type SE XHHW Aluminum Cable (SER/SEU): Ideal for above-ground service entrances, branch circuits, and panel feeders. These 600-volt, 90 degrees Celsius-rated cables are sunlight-resistant, flame-retardant, and meet NEC Article 338 standards for wet or dry environments. SEU cable includes a neutral conductor for use up to the service disconnect.

- XHHW-2 Aluminum Power Cable: This versatile cable finds applications in house construction, conduit, and approved raceways for services, branch circuits, and feeders in dry or wet locations. Available in various sizes and colors, it boasts low-friction installation without pulling lubricant.

- THHN/THWN-2 Aluminum Power Cable: As it is well-suited for feeders and branch circuits in commercial and industrial settings, this cable meets UL standards and VW-1 flame test requirements. It’s ideal for use in conduit and cable trays, with THHN rated for dry locations up to 90 degrees Celsius and THWN-2 rated for wet or dry locations up to 90 degrees Celsius (75 degrees Celsius for oil or coolant exposure). Similar to XHHW-2, it features low-friction, lubricant-free installation.

- Mobile Home Feeder – Aluminum Conductor: Designed to supply power in mobile homes, this 600-volt cable handles conductor temperatures up to 90 degrees Celsius. It meets various industry standards, including UL 44 and Federal Specification A-A-59544.

- 600 V Aluminum USE-2 RHH or RHW-2: This general-purpose wiring is well-suited for wet or dry locations with exceptional heat, abrasion, moisture, and sunlight resistance. It handles conductor temperatures up to 90 degrees Celsius.

Beyond Aluminum Building Wire

In addition to the building wire mentioned above, we carry a wide variety of other cable and wire products, including duplex, triplex, and quadruplex service drop cables, bare aluminum cables, MC armored cables.

Value-Added Services

We provide a range of value-added services to meet your specific needs. These include paralleling wires, cutting wires to specific lengths (6 AWG and larger), supplying pulling eyes, and offering same-day shipping for qualifying orders.

Partner With Classic Wire & Cable

Let Classic Wire and Cable be your one-stop shop for all your aluminum building wire needs. Our extensive inventory, competitive prices, and exceptional customer service ensure you get the right products at the right time. Contact us today to talk to our experts about choosing the right wiring for your application.

SO Portable Cord Cables (Copper)

SO Portable Cord Cables (Copper)